———–

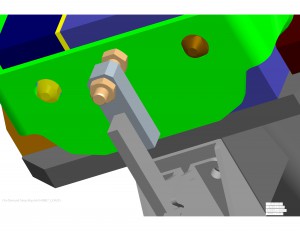

Machine Tool Fixtures, both Assembly and Weld Fixtures often require that a pin is placed into the hole of the product part to locate it.

We have talked before about using shims to help you reach precison in your weld jig or assembly fixture. Though life is perfect in CAD, and CNC’s are getting very precise, there still will be times when you need to design with tolerance variations in mind.

Before we get to the 32 Ways to position the pin with 3-way adjustability, let’s talk about tolerancing for the pin itself.

TOLERANCE THE DIAMETER OF THE PIN

When pinning you want the tolerance on the diameter of the pin to be close to the diameter of the hole in the product. Ideally the product should slide easily onto the pin without much effort and without being “sloppy”.

Our standard, and the standard of some of our customers is to take the “nominal” hole size of the product.

Nominal = (Upper Dimension Limit + Lower Dimension Limit)/2

So if the product diameter is .503 – .505, the nominal size is found by taking the lower limit and the upper limit added together and divide by 2. In this case, .504 inch diameter.

We then subtract .004 from that Nominal number and use a +/-.001″ tolerance on the pin.

Pin Diameter = Nominal – .004″

In our example, our pin diameter is .500″ +.001/-.001

If the Nominal was .75″, the pin diameter would be .75-.004 = .746 inch.

POSITIONING THE PIN FOR PRECISION

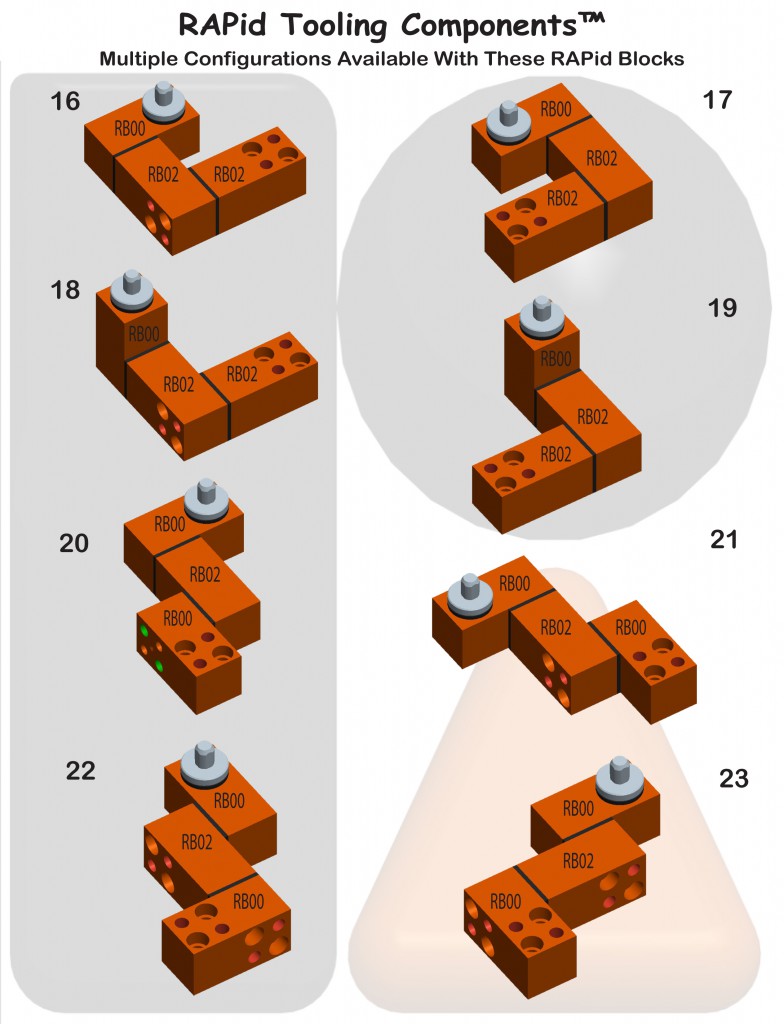

RAPid Blocks RB00 and RB02 are often used for precision adjustment of locating pins in a fixture.

Watch the video to see how to use RAPid Blocks RB00 and RB02 with a locating pin to precisely locate product parts in a fixture. Then look at the 32 different footprints you can create with the versatility of RB00 and RB02.

It really is 32 ways … the numbers start at zero-zero.

What do YOU do?

We had to remove the comments section of the Weld Fixture Design Blog. It was a hard decision, but in one day I received over 300 spam messages from spammers. But I would love to hear from you and what you have done to precisely locate pins, and your tolerance standards for the diameters of locating pins.

So I am going to write my email in code. news at rentapen dot com

THANK YOU!

I recently looked at Rentapen’s YouTube Channel to see how many people have been watching our videos. I was surprised and pleased to see that the first Weld Fixture Design blog lesson has received over 2,000 views! Thanks for watching!

If you haven’t signed up to be notified when the next Weld Fixture Design Lesson is posted, be sure to do so. All it takes is your name and email (The form is in the upper-right column of this web page). And I PROMISE not to spam or share your email with others who spam.

‘Til next time…